How to produce O-Ring common troubleshooting

O-rings are widely used in industries such as automotive, electronics, and medical etc, compression molding machine has become the preferred method for producing rubber rings due to its efficiency and precision! Today, let's discuss the process of its production and solutions to common problems to help you improve production efficiency!

Process of O- rings production

Material preparation: Select suitable rubber materials (such as NBR, EPDM, silicone, etc.), and perform mixing and preforming.

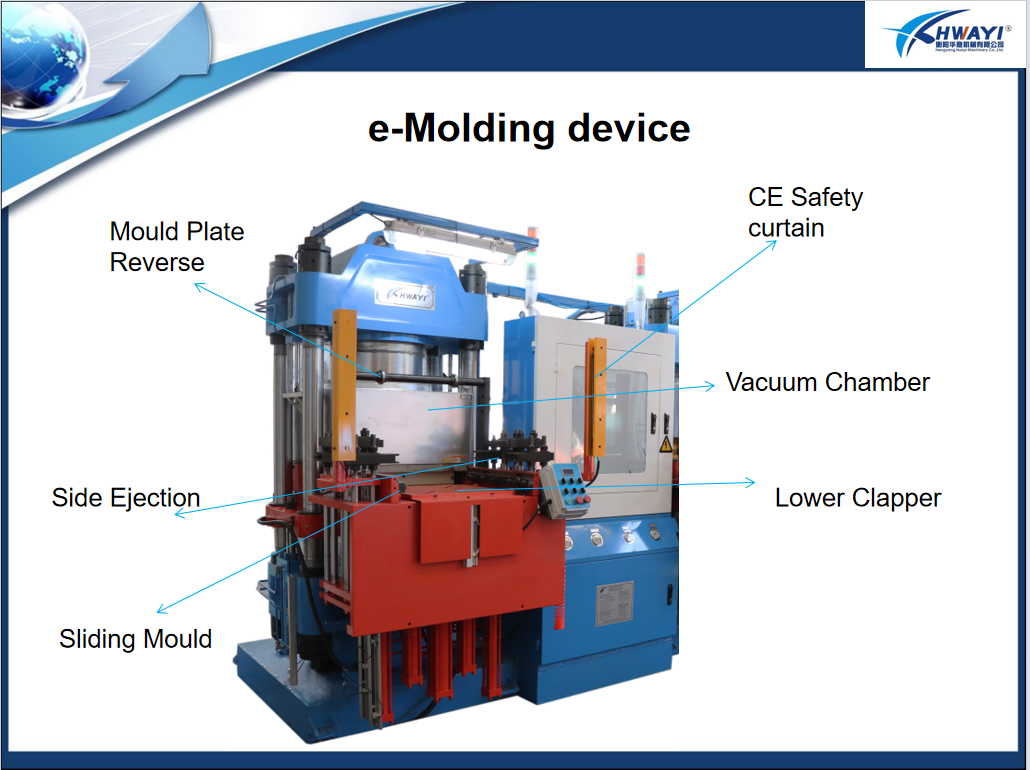

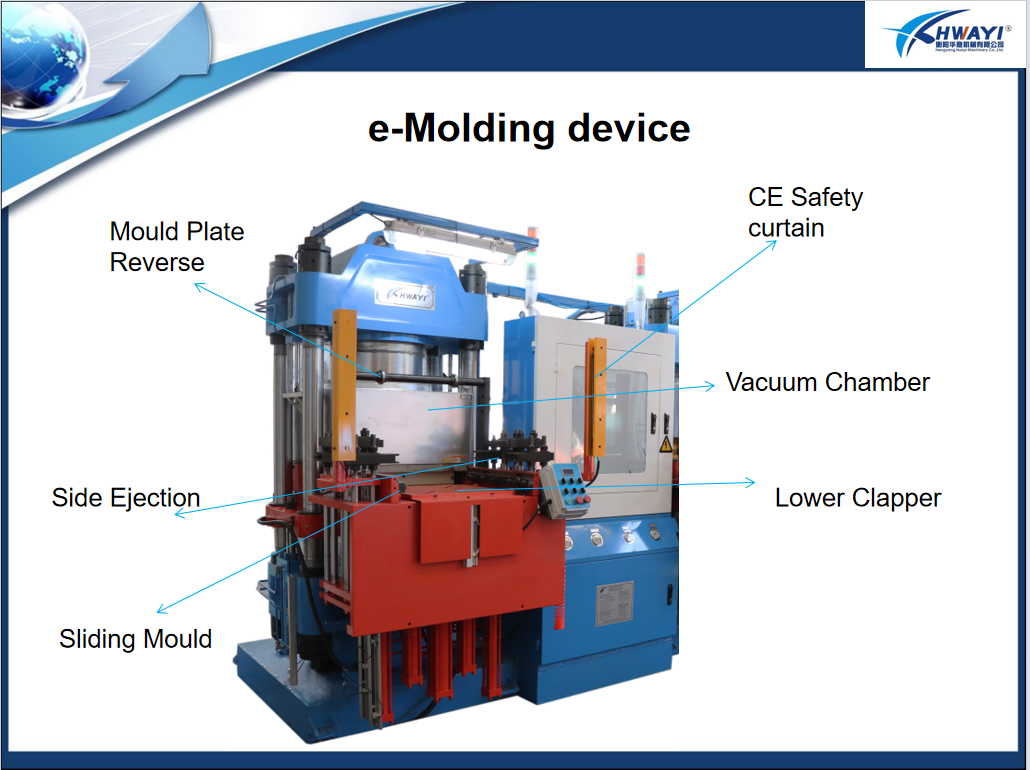

Mold Installation: Install high-precision molds ensure it matches well with machine.

Compression molding and curing: Put rubber strip into the mold, controlling temperature (typically 120-200°C) and pressure (80-150MPa), complete curing inside the mold.

Demolding and take products: mold open ,take out the products ,do some cleaning and de-flash, QC check, the whole productiong process completed,

Below is the video link show you the whole process .

https://www.facebook.com/share/v/1AzaXgTb1e/

Common Problems and Solutions

Bubbles: caused by too fast injection speed, poor venting.Pre-dry the material, reduce injection speed, optimize mold venting channels will be much helpful.

Flash: Caused by Insufficient clamping pressure, mold wear, excessive material, please Increase clamping force, repair mold, adjust injection volume.

Adhesive mold: Caused by insufficient release agent, mold surface roughness, incomplete vulcanization. please spray release agent, polish the mold, ensure complete vulcanization.

If you need more support, just leave us message and contact with our customer service.

Posted by Sharon.Yi

Email:machine@hwayimachine.com

Telephone:008613907344348